Ground-Mount Solar BOS Buyer’s Guide 2024 – Solar Builder Magazine

Solar PV can be mounted and energized atop of nearly any ground conditions you’ll encounter across the United States – from vast Western deserts to rocky, frozen Northeastern soils and everything in between.

But you already know that. Yesterday’s “challenging sites” are just the status quo in ground-based solar projects in 2024. It’s not just because those optimal flat sites are long gone, but also because structural balance of system (sBOS) and electric balance of system (eBOS) components have been tweaked to address and overcome those challenges the last several years.

In the 2024 Ground-Mount Solar BOS Buyer’s Guide, we showcase the latest and greatest in sBOS and eBOS systems for any ground-based solar project. We asked each manufacturer what’s new with this year, and to update their system specs.

Trends to note? In 2024, solar BOS procurement hinges on site/system optimization. Many products in this year’s Ground-Mount BOS Buyer’s Guide install more efficiently and perform more reliably than ever before. But do they complement each other?

- Is the tracker and/or cable hanger designed for the modules specified?

- Has the tracker company baked enough flexibility into the system?

- Is the wire management ready for the nuances of the module and tracker?

- Will that solar carport not just conform to the space given, but easily incorporate EV charging?

Any other tips? When kicking the dampers on that tracker system you’re looking at, here are 12 questions to consider.

- Has the tracker manufacturer conducted comprehensive multi-row static, dynamic, and aeroelastic wind tunnel tests within the past few years?

- Can the tracker manufacturer demonstrate that their tracker design adheres to the tolerances specified in their wind tunnel studies (e.g. array height, chord length, tracker length, GCR, natural frequency, damping, tracker length)?

- Can the tracker manufacturer provide evidence that their design accounts for all specified pressures and wind tunnel-specific load combinations beyond standard building code requirements?

- If dampers are required for the tracker manufacturer’s design, can they confirm that dampers were included in the aeroelastic wind tunnel tests and that the tested dampers accurately represent the final damper design?

- Has the full-scale tracker undergone thorough pluck testing?

- Has the tracker manufacturer performed component-level testing on each individual connection and system-level testing on full sub-assemblies and the entire tracker, and can they supply reports?

- Has the tracker manufacturer tested module-specific compatibility with their tracker design, and can they supply reports?

- Has the tracker manufacturer conducted full-scale lifecycle testing, and can they supply reports?

- Does the system exhibit slight twisting under extremely low loads (e.g. a person pushing on it), giving it a “loose” feel?

- Can the tracker be customized to meet project-specific requirements?

- Is the system capable of remote upgrades, enabling continuous improvements over time?

- Can you access sites remotely for easy troubleshooting?

In the Guide below, you’ll find submissions broken into the following categories:

- Featured company (sponsor of 2024 Tracker Month)

- Trackers and turnkey providers

- eBOS only

- Fixed tilt and canopy

NOTE: Click on on any product listed under each manufacturer in order to expand the section and see what it looks like, check out the specs, understand how to install it and learn a few other key features of the design.

If your company is missing, email our editors for inclusion.

Featured company

Total MWs installed in U.S. by year-end 2023: 24 GW

What’s new in 2024? Terrasmart continues its mission to provide smart solutions to its partners no matter the size or the terrain. The company continues to integrate products and solutions across the PV lifecycle to minimize risks and maximize returns. The most important product update is the TerraTrak 1P.

Specialties:

- Utility-Scale ground mount (20 – 300 MW),

- Single-axis tracker projects (20 – 150 MW),

- Foundation agnostic solutions.

- Canopies for surface lot and garage top,

- eBOS and project optimization software solutions.

Turnkey services

- Design & engineering: Geotechnical, structural, mechanical, electrical and civil engineers provide project-specific, value-engineered solutions.

- Turnkey construction: Specializing in professional surveying, drilling, screw, racking and panel installation.

- Surveying: Site topology and 3D mapping.

Number of pieces: 7 Superstructure Beam Members (above the vertical leg)

Certifications: UL2703, Edition 1; CPP Wind Tunnel Tested

Installation: Our adjustable and durable frame features less hardware, integrated electrical bonding, and included wire management resulting in reduced labor hours. Installation times are shortened by up to 36% through simplified connections, agile parts, and seasoned field teams. Compatible with ground screws that will eliminate refusal risk, increase install efficiency, and make projects more predictable. With one of the most experienced field teams in the industry, we have priceless insights that allow us to overcome challenges and streamline processes to ensure projects are completed on time.

Advantages: With a slope tolerance of 36%, our racking can accommodate high slopes and undulating terrain. Landscape orientation is bifacial compatible to maximize potential backside power yield. Durable mechanics can tolerate wind speeds up to 170 mph and 100 PSF ground snow loads. Our seasoned field team prioritizes accuracy, safety, and efficiency. Foundation consultation from an unbiased partner, based on your unique project site. No matter the terrain or weather, we’ll provide the right solution. Our versatile design enables numerous configurations allowing us to meet your unique needs and bring solar to more fields.

Number of pieces: 7 (1 foundation, 6 racking components & bracket assemblies)

Certifications: UL2703, Wind Tunnel Tested

Installation: Engineered with flexibility in mind, the design incorporates continuous rows to mitigate topographic changes and minimize the number of foundations required. The system can be altered to multiple foundation options, with the base option being driven piers. Proprietary electrical bonding is integrated into the racking system, as well as other solutions for wire management. Pre-assembled parts reduce the number of connections required to be made in the field, minimizing Installation time.

Advantages: The standard engineering of the system is designed to accommodate slopes up to 15%. With several GW deployed across all 50 states, the system is durable and robust enough to accommodate the heavy snow loads in the Northeast, along with the high wind speeds of Hawaii. Our team of professional designers, licensed engineers, and dedicated project management collaborates to ensure projects are delivered in an effective manner and able to operate efficiently. We design each system to site specific environments, helping our partners to maximize the return value on each opportunity.

Number of pieces: 7 (2 foundations, 5 racking components & bracket assemblies)

Certifications: UL2703, Wind Tunnel Tested

Installation: Designed with a low tilt and clearance, the dual foundation design supports a higher number of PV modules per foundation than standard fixed-tilt systems. The low clearance makes for easier access to assemble components, all of which contain one bolt size. Components are shipped to site pre-assembled, requiring less hours for assembly in the field.

Advantages: For flat sites with low wind and snow loads, this system helps to maximize the PV output with a high ground coverage ratio (GCR). The low tilt and low clearance of the structure reduces row spacing, allowing for more PV modules to be deployed in a given area. The number of racking components is also reduced, reducing the installation time required to assemble the structure. A proprietary design in the components bonds the system, helping make wire management less intrusive.

Surface lot canopy, Garage canopy

Product description: Terrasmart offers a variety of canopy structures to accommodate any parking surface including longspan, inverted, perimeter and aisle structures. Our structures and foundations are engineered for environmental loading and any subsurface/soil conditions. Accessory options such as water management, snow guards, facia trim, and multiple coating options are available. A big part of our value is our ability to work with our customers on the conceptual design phase to ensure the best possible system is designed for each project and budget.

Construction process: Pre-construction design identifies risk up front for smooth project planning. Smart scheduling and through bolt connections result in less disruptions on site and faster installation time. We’ll work with you to ensure installation is phased in the most efficient way possible.

Differentiator: Terrasmart provides a single source for design, engineering, manufacturing, and installation. With projects covering most of the U.S., we’ve completed projects from Massachusetts to Hawaii. Terrasmart has deployed over 270 MW of canopy systems ranging from 100 kW up to 14.8 MW. With over a decade of projects on the books, we have a long track record of delivering projects at every scale — on time and on budget.

AC & DC combiners, recombiners, disconnect enclosures, wire solutions

Material: Copper or aluminum

Installation: Our combiners are customizable so you can install faster in the field. Our prefabricated wire solutions allow for plug and play connection in the field requiring less labor and time on site.

Key feature: What sets us apart is our expertise and ability to design to specific project needs. We have completed projects ranging from 1 MW to 200+ MW. We can create custom solutions at any scale without sacrificing quality and timeliness. Strong product knowledge from the office to the shop floor allows for best-in-class lead times. Our 100,000-sq-ft facility in the U.S. enables us to scale our production based on demand. With 8.5 GW of solar deployed with Terrasmart’s eBOS products, you can trust our team to deliver reliable, on-time products.

Brand specific racking/tracker partner integrations: Our combiner and wire solutions can support any racking in the industry. You will find efficiencies when pairing our eBOS products with the Terrasmart racking portfolio including GLIDE Agile, GLIDE Wave, GLIDE Fuse and TerraTrak.

[embedded content]

www.terrasmart.com | in**@te********.com | Webinar coming April 24

Trackers and turnkey providers

Specialty: OMCO has six manufacturing facilities –in Arizona, Alabama, Indiana and Ohio – and can offer highly competitive pricing and the shortest lead times in the industry.

Total MWs installed in U.S. by year-end 2023: 10.5 GW

What’s new in 2024? OMCO Solar celebrates the milestone of having shipped 10.5 GW of its premier solar mounting structures, comprised of 8 GW of contract manufacturing solutions and 2.5 GW of OMCO Solar designed products. In September 2023, OMCO Solar announced a $10 million plus solar manufacturing investment in its second Alabama plant opening Q1 of 2024. This significant expansion will bolster OMCO Solar’s overall manufacturing capacity to over 10 GW across its six facilities, encompassing more than 700,000 square feet of manufacturing space throughout the U.S. The company continues to maintain a world-class, reliable domestic supply chain, as well as the shortest lead times in the industry.

Turnkey services

- On-site pile testing: This includes a third-party stamped report that can be used for foundation design, which is a cost-effective alternative to geotechnical reports.

- Precision Engineered — Engineering Design & Site Optimization. Can optimize a project design and customizable solutions to maximize the benefits of OMCO products.

Posts per row: Dependent on soil conditions, type of posts and row length — average is 11 to 13 per row.

Row lengths: While 96 modules per row is most common, OMCO Solar can customize to accommodate up to 112. Unique bearing technology allows long straight rows — 4 strings when others can only mount 3 — fewer motors and controllers per MW.

Slope Tolerances: Up to 15% for a North-South Slope

Design: OMCO Origin 2L (2-in-Landscape) Bifacial Trackers are primarily constructed of galvanized steel and cast aluminum. Bearings include a wear surface composed of a unique long-life, low-friction, self-lubricating acetal blend. A balanced design allows for more accurate targeting and reduced energy consumption. Some subassemblies are factory preassembled and shipped as single units for labor, time and cost savings. The unique bearing adjusts to accommodate post misalignment. OMCO Origin 2L Bifacial Trackers are open on the back — no torque tube blocking the cells — for highest energy production. The height of the tracker is low — like 1-in-portrait trackers — to minimize installation labor. Foundation options include OMCO-produced driven C posts (preferred) and driven I or W posts, and ground screw foundations.

Advantages:

• Factory Preassembled: Some subassemblies are supplied as single, preassembled units for installation labor savings.

• Balanced Design: Axis of rotation at the center of mass of the table — improves targeting accuracy, increases energy production and minimizes energy consumption.

• Long Wear Life: Bearings tested to more than 40 years equivalent life.

• 7 Dimensions of Adjustment: Bearings adjust to accommodate post misalignment, avoiding project delays.

• Over 20% Higher Back Side Production: The open back allows uniform backside irradiance, which is critical for long cell and module life.

• Shortest Lead Times: Partners benefit from expedited delivery due to OMCO Solar’s four strategically located U.S. manufacturing plants. Lead times are typically 8 to 12 weeks.

Domestic Content: OMCO makes all structural components with domestic steel and is well positioned for IRA ITC benefits.

Number of pieces: 8 Typical Components + Hardware

Certifications: ISO 9001:2015 Standard, UL 2703 Ed. 1, CPP Wind Tunnel-Tested, NEC Compliant

Terrain Articulation: Accommodates up to a 20% grade change

Installation:

- For a pile-driven foundation, posts are driven into the ground.

- Pre-assembled tilt bracket assemblies are bolted onto the piles.

- Lateral beams are then connected by fasteners to the tilt assemblies.

- Modules are secured with fasteners directly onto the beams to provide a secure bond.

Advantages: Pre-Assembled tilt assembly optimizes packaging & shipping, reduces on-site labor requirements, accelerates total build time, and eliminates loose hardware along with third party grounding devices. This in turn accelerates the assembly process. All structural components are manufactured in OMCO Solar’s six U.S. manufacturing plant facilities. With the company’s factory-direct model and domestically sourced supply chain, OMCO Solar consistently delivers quality solar mounting solutions with the shortest lead times in the industry.

www.omcosolar.com | Sales: in**@om*******.com

Specialty: Utility-scale

What’s new in 2024? Trina Solar has launched the 2nd generation of our Vanguard 1P single-axis tracker. Some of our key design features include longer-row capabilities while maintaining tracker stability. As a PV module and tracker OEM, we ensure the Trina tracker is compatible with the largest PV modules in the market (700W+).

- Number of pieces: Up to 120 modules per tracker

- Posts per row: 9

- Row lengths: 72 meters

- Slope tolerances: 20% N/S, 10% E/W

- Certifications: UL, IEC

Agile 1P is a one in portrait dual-row single axis tracker. There are two slewing drives on each row connected by cardan transmission bar, both rows share one motor and one controller. Agile 1P utilizes W pile as its foundation along with patented spherical bearings and highly reliable square torque tube Additionally, Agile 1P features TrinaClamp for fast reliable installation and lower BOS/CAPEX.

The construction starts with driving the piles, installing the bearing supports, bearing housing and torque tubes. Adjustments can be made prior to applying the torque and if re-adjustment is needed, it can be done. The next step is installing the joining clamps to connect the torque tubes. After that, the drive system is installed. This consists of a front support between the piles, the transmission lever, the push / pull bar, and the linear actuator. After that the purlins and modules are installed, then the TCU, self-powered panel and grounding strap.

Advantages:

- Features industry leading ±60°tracking range and higher resultant energy output

- Capable of installing up to 120 modules per tracker

- Capable of withstanding higher critical wind speed and reducing aeroelastic effect on trackers

- Capable of providing more energy gain by including SuperTrack Algorithm

- Capable of mitigating extreme weather such as wind, snow, hail and flood

- Number of pieces: Up to 120 modules per tracker

- Posts per row: 7

- Row lengths: 68 meters

- Slope tolerances: 15% N/S

- Certifications: UL, IEC

Vanguard 2P is a two in portrait independent single axis tracker. The newly designed tracker features an innovative multidrive system comprising of three linear actuators connected by cardan transmission bar. Vanguard 2P utilizes W pile as its foundation along with patented spherical bearings and highly reliable square torque tube. Additionally, Vanguard 2P uses reinforced purlins to optimize layouts with the new Trina Solar 600W+ large format modules.

The construction starts with driving the piles, installing the bearing supports, linear actuator supports, bearing housing/ lever /torque tube pre-assembly. Pre-assembly is an assembly of several components pre-assembled on the ground and installed on the structure for a more efficient installation process. Each project site will have different pre-assemblies for different sections of the tracker. The install manual and construction sequence documents will be project specific and optimized for an easier installation process. Adjustments can be made prior to applying the torque and if re-adjustment is needed, it can be done.

The next step is installing the linear actuator in the specified positions, and then the joining clamps to connect the torque tubes. After that, the transmission system supports are installed on the torque tubes. Following that, the transmission bar and cardon are installed. After that the purlins pre-assembly is prepared and installed before installing the modules. Then the TCU, self-powered panel and grounding strap.

Advantages:

- Features 2P tracker industry leading ±55°tracking range and higher resultant energy output

- Capable of installing up to 120 modules per tracker

- Capable of adapting to more challenging terrain with fewer pile design

- Capable of withstanding higher critical wind speed and reducing aeroelastic effect on trackers by multidrive system

- Capable of providing more energy gain by including SuperTrack Algorithm

- Capable of mitigating extreme weather such as wind, hail and flood

- Easier for O&M vehicle’s accessibility

Specialty: With over 90 GW of smart solar trackers operational or under fulfillment around the world, Nextracker NX Horizon solar tracker systems are well-suited for both utility-scale and DG solar projects.

What’s new in 2024? In February, Nextracker announced it has surpassed 600 projects delivered in its distributed generation (DG). To support its growing global ecosystem of DG solar infrastructure, the company entered into a new agreement with channel partner RP Construction Services who provide Nextracker products and systems to address the smaller utility-scale market and DG solar power generation applications typically under 30 megawatts.

![]()

Row length range: Configurable per module type, string length, and site layout

Slope tolerances: N-S site slope and E-W site slope up to 15%. N-S terrain following conforms to native land contours. Angular tolerance configured to site conditions.

Certifications: UL 2703, UL 3703, IEC 62817, CSA

How does it install? NX Horizon-XTR all-terrain solar tracker delivers enhanced yield while minimizing environmental impact on project site. Its independent-row, balanced tracker design and software solutions enable deployments in all geographies, sizes, and most terrains—from flat sunny and rectangular sites to irregular more diffuse and undulating locations. The NX Horizon platform allows EPCs to conform to sites with irregular and rolling terrain layouts and can eliminate the need for additional grading, lowering costs, and using space more efficiently while helping to boost energy yield and financial returns for both utility-scale and DG project owners. The latest version, XTR-1.5, doubles XTR’s ability to conform to sloping terrain, further expanding opportunities for solar development on challenging sites.

Advantages: NX Horizon-XTR, a new variation of the industry-leading smart solar tracker NX Horizon, conforms to the natural terrain, generating a series of benefits, such as:

- Eliminating cut-and-fill earthworks

- Reducing pier lengths

- Easing permitting

- Softening environmental impacts

This new smart solar tracking system also contributes to accelerating project construction schedules that help save time and money.

Unique software capabilities? When combined with its flagship NX Horizon solar tracker platform, Nextracker’s TrueCapture yield optimization and control software forms a powerful combination that can boost performance, save cost and maximize return for project developers and asset owners. TrueCapture combines advanced sensors, weather forecasting, and machine-learning technologies to maximize energy generation for new and existing solar power plants. The software’s intelligent, self-adjusting tracker control and yield optimization system boosts solar power plant production by continuously optimizing the tracking algorithm of each individual row in response to site features and changing weather conditions.

Specialty: Nevados is the premier solar tracker company for PV power plants built on sloped and rolling terrain. We offer innovative all-terrain trackers paired with a comprehensive software suite in an integrated technology platform that optimizes solar performance, improves plant reliability and respects the natural landscape.

What’s new in 2024? There will be several product features to be released in 2024 based on discussions with customers on key needs. More information about these will be available as release dates near.

Row length range: 1, 2 and 3 strings with Large Format Modules and 16 strings for First Solar S6+

Slope tolerances:

- Up to 26% (~15 degrees) at every single foundation

- 37% (~20 degrees) max slope N-S and E-W

Avg. row construction time: Installation studies are in process now with a third party

Certifications: UL 2703, UL 3703

Installation: The same features that allow the tracker to perform on extreme terrain, without grading, give it an installation benefit – the bearings allow for a lot of tolerance during installation, alleviating costly remediation activities for the EPC. The design of the system lends itself to a very simple bill of materials, making onsite staging and inventory planning easier.

Unique software capabilities: The proprietary Nevados TRACE software computes optimal row by row tilt schedules on any terrain to avoid any row to row shading. This software also enables energy modeling in PVSyst on any topography with novel row by row tilt schedules which ensures the right revenue model is financed before construction.

Advantages: The key advantage of the Nevados ATT comes from the ability of the bearings to “articulate” and its “disconnected” torque tube architecture, which lets the solar row naturally follow the terrain profile. Because of the bearings are designed to articulate, the tracker becomes quite “adaptive” – adapting to changes in the site environment after installation such as differential settlement of the local soils or frost heave forces lifting up piles. This allows the owner to continue operating the site without costly downtime and remediation.

Unique software capabilities: Nevados ATT comes out of the box with its terrain aware backtracking controls. We use an internally developed tool to evaluate the exact project terrain profile and iterate rotational schedules for each row until row-to-row shading is minimized. Nevados does not charge extra for this service.

Specialty: Projects of all sizes, 20-100 MW sweet spot. RP Construction Services, Inc. (RPCS) is the nation’s leading contractor and Array Technologies single-axis tracker expert.

Total MWs installed by year-end 2023: 4.7 GW

What’s new in 2024? RP Construction Services (RPCS) is now offering single-axis trackers from Nextracker, the trusted global market leader in solar tracking technologies, to self-perform their design and stamped engineering with warehousing, kitting, and delivering Nextracker’s NX Horizon smart solar trackers. This new partnership allows RPCS to continue to service its expanding customer base, providing expert services to accelerate and ensure the best value for tracker projects across the country.

Turnkey services: Design, structural engineering, procurement/supply, mechanical installation, and specialty services to EPCs, developers, and municipal utilities.

Number of pieces: 30 individual part types per row

Posts per row: Up to 26 (varies based on design criteria)

Row lengths: 100+ module row lengths, up to 126 meters long (varies based on module size and weight)

Slope tolerances: 15 degrees N/S; 37 degrees E/W

Certifications: UL 2703, 3703 and IEC 62817

Design: The Array tracker can be custom designed, supplied, and installed by RPCS, Array’s trusted partner and leading Array tracker installer. RPCS is dedicated to offering customers the best overall experience, with a team of over 300 tracker experts to offer support. Linked rows are powered by an AC motor, an articulating driveline, and a rotating gear drive. Up to 32 rows can be controlled by just one motor.

Advantages: The DuraTrack boasts up to 25% energy gain over fixed-tilt systems and has an unparalleled track record of high uptime (99.996%), 7% lower LCOE, and 31% lower lifetime O&M with zero scheduled maintenance. The Array tracker utilizes the fewest motors per MW, with 167 times fewer components, and is the most adaptable tracker in terms of terrain, with low grading and the ability to be readily deployed on the most challenging parcels. In addition, the tracker is designed to mitigate high wind loads, snow loads, and inclement weather like hail.

Row length range: Configurable per module type, string length and site layout.

Slope tolerances: Up to 15% N-S and 15% E-W

Certifications: UL 2703, UL 3703, IEC 62817, CSA

How does it install? With pre-assembled components, no drive linkages, no AC wiring, self-aligning rails, and available XTR terrain following upgrades, NX Horizon is fundamentally faster to install, requiring less construction labor, less grading, and less total project capital cost.

Advantages: NX Horizon’s patented independent row, self-powered tracking system provides reliable performance across the widest possible range of site conditions. Simple, robust hardware, including self-aligning module rails and vibration-proof fasteners, enables rapid installation and long life without maintenance. Mechanically balanced rows minimize tracking power requirements and pair with a time-proven, rugged drive and control system for maximum durability and uptime. NX Horizon’s decentralized architecture with intelligent communications supports maximum layout adaptability, flexible construction and commissioning sequencing, advanced tracker functionality, and over-the-air updates.

Unique software capabilities? TrueCapture combines advanced sensors, weather forecasting, and machine-learning technologies to maximize energy generation for new and existing solar power plants. The software’s intelligent, self-adjusting tracker control and yield optimization system boosts solar power plant production by continuously optimizing the tracking algorithm of each individual row in response to site features and changing weather conditions.

Specialty: Utility-scale solar trackers

What’s new in 2024? At RE+ 2023, FTC Solar debuted a one module in portrait (1P) Solar Tracker Solution called Pioneer. The Pioneer design will also allow for the use of ground screw mounting systems to overcome challenging sub-surface conditions.

Slope tolerances: 17.5% north-south tracker row allowance

Installation: A proprietary fast-module hang technology and fewer overall fasteners save installation time. The Pioneer design also allows for the use of ground screw mounting systems to overcome challenging sub-surface conditions.

Advantages: Pioneer achieves a full 18%-36% pile count reduction per megawatt vs. the current industry-leading solutions by volume. Pioneer enables up to 5% greater energy output for the same site compared to the competition. The system accommodates wide format modules with no torque tube dimpling or through-bolts required to index the module to the tube. This allows for module changes and retrofits. In addition, Pioneer will operate independently from the grid during outages and is self-powered with a high-energy battery for up to 3-days overall backup, offering increased energy resilience.

Slope tolerances: 10 degree N/S slope tolerance

Installation: The Voyager+ allows for 7 posts per row (1 drive, 6 typical) with a typical embedment depth of 6 to 10 ft, which is 60% fewer posts than 1P designs. Together with 40% lower installation time than other 2P systems, this results in lower costs and fewer manhours.

Advantages: Voyager+, the next generation of its single-axis Voyager tracker, engineered to provide compatibility with new large-format solar modules now entering the marketplace. The large modules entering the market are built to incorporate larger solar cells. With these larger 182 mm and 210 mm cells, the modules can achieve power output exceeding 500 watts. Voyager+ supports these larger format modules and will be able to accommodate multiple module sizes from a variety of solar manufacturers.

What’s new in 2024? Soltec announced the launch of its new SF7 USA solar tracker, specially designed for the American market.

Mounting tolerances: Range from 20 to 40 inches. Can be installed on slopes of up to 17%.

Installation: Soltec pre-assembles most components, so the installation includes few steps. Locating the parts and pieces needed at each step is quick. All of this results in substantial savings in both time and financial resources.

Design: The tracker features an electronic system that incorporates wireless communication designed to withstand low temperatures.

Software: TeamTrack system delivers up to 6.8% more yield, a function that minimizes shading losses between rows, especially on uneven terrain. Diffuse Booster technology allows for optimal energy generation, even on cloudy days, by capturing diffuse radiation. Dy-WIND methodology, solar tracker response to wind is ensured, preventing damage to the plant during heavy precipitation.

eBOS only

Specialty: CAB Solar Cable Management delivers safe, strong and durable support for all types of wiring in utility scale, ground-mount solar power plants.

MWs installed in North America by year-end 2023: 100 GW+

What’s new in 2024? In 2024, CAB Solar will be going through the registration process of ISO 9001 Certification. ISO 9001 is defined as the international standard that specifies requirements for a quality management system (QMS). Organizations use the standard to demonstrate the ability to consistently provide products and services that meet customer and regulatory requirements. CAB Solar is expecting certification by the end of the third quarter. This certification demonstrates the consistency and high-quality of the CAB Products line along with improving efficiency and customer satisfaction.

Key Feature: CAB Solar’s uniquely engineered grounding messenger wire, made of a copper-clad steel composite, is strong enough to provide support functionality and evaluated to be conductive enough to serve as an Equipment Grounding Conductor (EGC) and a Grounding Electrode Conductor (GEC) with #3, #2 & #1 equivalents available.

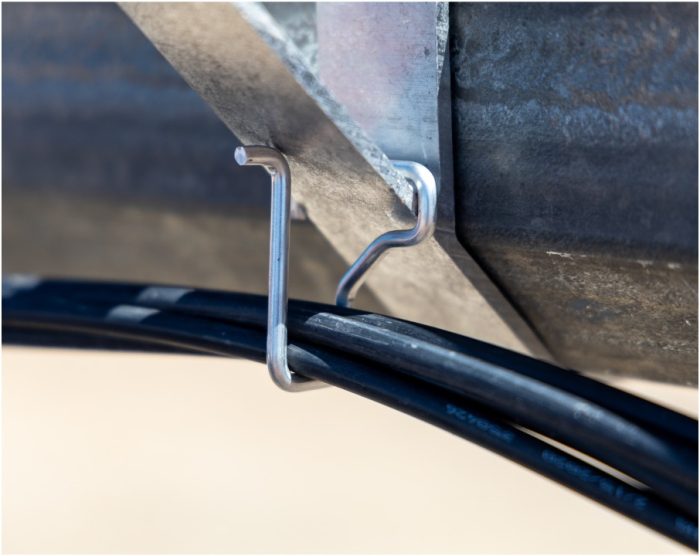

Key Feature: CAB Solar’s durable Mid Pier Bracket made of galvanized steel and hardware with a tin-plated bronze grounding clamp provides a clear and sturdy path for grounding in any type of utility-scale project. CAB Solar’s patented Integrated Grounding System is safety listed to UL 2703 by Intertek.

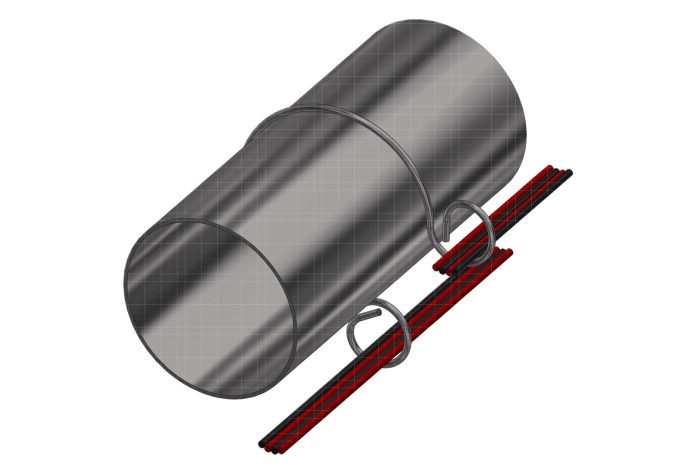

Installation: CAB Solar’s Multi-Carrier Torque Tube Hangers for under-panel cable management offer a tight, snap-on fit over most torque tubes or fixed tilt structures. The low profile is especially beneficial for reduced shadowing with bifacial panels. The innovative spiral design holds large bundles of cable safely and securely, while simplifying upgrades, maintenance and troubleshooting.

Key feature: CAB Solar Products are manufactured in the United States by the Cambria County Association for the Blind and Handicapped. This non-profit provides numerous services as well as employment opportunities for over 350 persons with disabilities in Cambria County, Pennsylvania. Purchase of CAB Products helps support this mission.

Key Feature: CAB Solar offers a variety of innovative solutions for your cable management needs. Not all solar projects are “one-size fits all” designs. CAB’s team of proficient engineers and experienced solar project developers can assist you to customize solutions for your utility-scale projects.

Specialty: AWM’s utility-scale solar innovations include the Arden Messenger Cable Hanger, the Solar LOTO and the Bonsai Module Cable Hanger. Arden Cable Hangers are durable yet cost-effective, highly functional without added complexity and rapid to install.

Total MWs installed in U.S. by year-end 2023: 8+ GW

What’s new in 2024? AWM’s expanded solutions in 2024 now include the HELIOS Beam Rod, the PHOTON Toolkit and SUMAC Messenger Support. In addition to the Solar LOTO and Bonsai Module Cable Hanger, AWM also announced significant performance improvements to its next-generation Arden Messenger Cable Hanger. Arden Hangers are uniquely designed to optimize the arrangement of solar cables, which significantly increases the total ampacity, or maximum current that can be run through a wire continuously without risk of degradation or failure. Prioritizing value engineering in order to build rugged, durable solutions, AWM designs its products to last the lifetime of all utility-scale solar power plants.

Material: Every component of the AWM Bonsai Cable Hanger is made of exceptionally durable alloys and is free of polymeric material, with a life expectancy exceeding 40 years. The products, which are certified under UL1565, can withstand all weather conditions: temperatures from -40°C to +150°C, extreme ice and snow loads, and worst-case corrosive environments.

Install: AWM offers the Bonsai Cable Hangers in a variety of flavors, including bifacial-friendly hangers which are mounted near the torque tube on module clamps and can be installed prior to module installation. Installation is typically performed with one hand, enabling a faster installation of hanger and cable. Bonsai meets all the latest requirements in the industry; additionally, AWM provides a highly detailed drawing set which will guarantee golden row approval.

Key feature: Bonsai Cable Hangers are highly customizable and tailored, so regardless of the tracker or module type, we offer the most competitive value-engineered offering on the market. In addition, thanks to our strategic and nuanced design, our solutions also help the installer reduce time and costs. For example, if the Bonsai Cable Hanger is on the clamp of the tracker, our unique design ensures installation velocity, and results in less cabling needed on the site. In short, AWM Bonsai Cable Hangers ensure lower costs with less cable hangers needed, and a more efficient, cost-optimized option for installers and developers.

Material: AWM’s first-of-its kind safety lock-out device has made yet another leap forward in the industry. The AWM Solar LOTO is a newly released locking dust cap. The single part is OSHA compliant and serves as both a safety LOTO device and a dust cap during energization or maintenance. Designed to be dust and water resistant and certified to IP67, AWM’s Solar LOTO ensures safety while protecting against environmental contaminants.

Install: AWM’s Solar LOTO installs rapidly and easily. The device attaches directly to the connectors and requires a special disconnect tool to remove it. This significantly decreases the risk of accidental electrocution during energization and maintenance.

Key feature: The AWM Solar LOTO is a groundbreaking product designed to enhance safety and prevent accidental energization of string or feeder cables. Unlike typical dust caps that can easily fall off, this long-term dust cap locks securely onto the connector, ensuring maximum protection against dust and other contaminants. Additionally, the AWM Solar LOTO can prevent super strings, a phenomenon that can occur when too many solar panels are connected in series. With its innovative features, the AWM Solar LOTO is revolutionizing the solar industry and setting a new standard for safety and reliability.

Total MWs total installed in U.S. by year-end 2023: 3+ GW

What’s new in 2024? Snake Tray has designed a new series of cable hangers and we have just launched our newest system for Solar Snake Max that can accommodate cables from 750-1250 Kcmil. The new portfolio of solar cable hangers provides durable, cost effective, and expeditious installations for managing cables. Our new hangers will greatly simplify new project installations, repowering, system expansions, upgrades, O&M, and troubleshooting over the life of the project. SnakeTray also has a new open air design cable conveyance system for battery energy storage systems and EV charging stations.

Snake Tray’s New Battery Energy Storage System

Benefits:

- Open air design means no trenching, substantially lowering the cost of labor and materials.

- NEC 310.15 code compliant cable separation requires no derating of the cables.

- Snap together components require no tools.

- Accommodates cables ranging from 350 Kcmil up to 1,250 Kcmil.

- Compatible with any inverter style and battery storage system.

- Made in the USA.

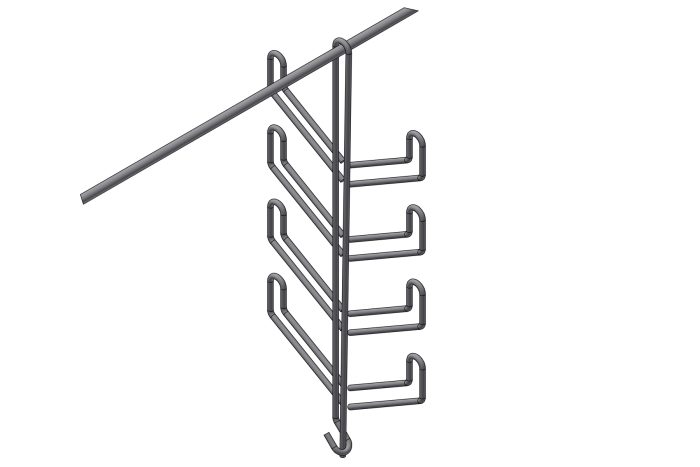

String and Feeder Cable Hanger

As utility grade systems grow in size so does the size of string cables. Utilize Snake Tray’s tree hanger with a capacity of up to a quantity of 16, 750 Kcmil cables per hanger. Ideal for larger scale projects and can even be stacked to create a modular system to further increase capacity. The side loading feature offers quick access to installing and maintaining cables for reduced labor costs. No trenching for minimal ground disturbance. The large capacity loops will handle any size of cable bundle easily and effectively.

String Cable Hangers for Messenger Wire

The new portfolio of solar cable hangers provides durable, cost effective, and expeditious installations for managing cables under solar panels. Our new hangers will greatly simplify new project installations, repowering, system expansions, upgrades, O&M, and troubleshooting over the life of the project.

Key feature: Quickly top load the PV cables directly into this light weight double pocket hanger with a squeeze loc feature that quickly attaches onto the messenger cable to secure the string cables. Significantly reduces time and labor by requiring no tools.

Key feature: Tube hangers point in the right direction and are designed with innovative features that provide a dual round section to manage cable as trackers move daily up to 67 degrees following the sun from east to west. Our hangers can be custom designed to fit any style of fixed tilt or tracker for a secure fit over any style torque tube or fixed tilt structure.

Specialty: Gripple designs and manufactures a range of solutions for utility scale solar projects providing faster installations, material savings, logistical benefits and reduced project CO2. The Gripple solar offering includes above ground cable management systems for EBOS as well as a range of lightweight bracing and anchoring kits for ground-mount solar array installations.

What’s new in 2024? New second generation CableSmart Single Hanger – The new and improved Gripple CableSmart Single Hanger allows for management of larger cables up to up to 2.36 in (60 mm) in diameter and can carry up to 8x 750 kcmil cables. New Power-Tie Permenant Cable Tie Solution – Power-Tie, our wire cable tie, changes the game in direct fix cable management. Engineered for lasting performance, Power-Tie combines the robust strength and endurance of steel banding with the ease of install and versatility of cable ties.

Gripple’s CableSmart above ground cable routing system is super quick to install, designed to last the lifetime of your site, and helps protect your cables from abrasion and wear. Gripple’s Messenger Kit is the fastest and easiest to install on the market thanks to the Dynamic wire joiner/tensioner. Alongside this, Gripple also supply messenger brackets and a range of hangers featuring side cable loading for easy installation and access. Gripple’s hangers have been specifically designed to protect cables, with a wide surface area to prevent pinch points and abrasion over time. The snap on locking mechanism which attaches hangers to the messenger wire also prevents movement, ensuring hangers and weight remains evenly spaced long term.

Materials: All materials are designed to last 30 years +, and are tested between -40 and +90 degrees Celsius. Hangers are made from UV stabilized Polycarbonate, with the messenger wire made from corrosion-resistant Zinc Aluminum.

Installation: Installation is quick and simple, requiring just hand tools and minimal training. First contractors install the Messenger Kit which can be attached to end posts using eyelet fixings or intermediate ground mount frames using the Messenger Brackets. The Messenger Kit is quick to tension using the Gripple Dynamic tensioner, making the system so much faster than traditional turnbuckles. Once the Messenger Kit is secure, contractors can attach the Hangers at regular intervals along the messenger wire. The Hangers feature a locking side loading gate which makes loading cables easy and O&M access simple.

Basics: Power-Tie is Gripple’s wire cable tie. Engineered for lasting performance, Power-Tie combines the robust strength and endurance of steel banding with the ease of install and versatility of cable ties.

Material: Power-Tie’s wire joiner is manufactured from Zink Alloy and includes corrosion resistant Sintox Ceramic wedges. The wire rope is 316 stainless steel and the cable protection strap is made from HDPE with UV and FR additives. It is tested for -40 to +194 Degrees Fahrenheit (-40 to +90 Celsius) and has been designed to last 20+ years).

Installation: Place the strap over the cables then insert wire rope into the entry channel while holding the cables in place. Pull the wire rope tight until cables are secure and use the retention clips to secure any excess tail wire. Use the Flag Key to release the GripTie allowing for adjustment or re-installation.

Key features

- Simple Install – As easy and fast as a traditional zip tie

- Reduced Replacement Costs – Designed to last 20y+

- Use Anywhere – with 3 size options you can use on any type of structure

- High Strength – Comparable with steel banding and ties giving you confidence to use anywhere

- No Waste – 3 size options with no need to cut excess wire on site

- Safe To Install – Tool free with no RSI risks

Gripple engineers have developed a lightweight solar frame bracing kit which provides comparable structural performance to heavy traditional steel bracing, at a fraction of the cost. By replacing heavy steel cross sections with strong but lightweight wire rope bracing, you can significantly reduce material, transportation, and logistics costs, as well as embodied CO2. In addition, Gripple bracing kits are fast and simple to install using just hand tools, and are delivered in small boxes making on-site material handling easy compared with lengths of steel and powered machinery.

Material: All components are made specifically for outdoor use with a life expectancy of 30+ years in the harshest conditions. Gripple’s wire rope is coated with corrosion-resistant Zinc Aluminum and can be integrated as part of the frame with custom hot dipped brackets, or looped around existing fixing points. The internal gripping mechanism consists of a sintered ceramic roller offering a superior strength to alternative tension-only bracing systems, with a load rating of up to 3,860 lbs.

Install: The two-way locking device known as a PV Dynamic Tensioner allows you to install a brace quickly and easily between two piles. Applying pre-tension using a fast and unique tensioning tool, the PV Bracing Kit will ensure the frame stays rigid, eliminating misalignment that might occur due to external forces and environmental loads. The ready-to-use kits are fast and lightweight, drastically improving health and safety on-site.

Key feature: Kits come in oversized lengths to allow for greater flexibility in the tolerance of frame installation and to support a greater variety of mounting systems. To aid the installer, the Dynamic Tensioner component is releasable, allowing the product to be adjusted prior to tensioning.

Gripple offers a range of lightweight Solar Anchoring Kits which attach to solar frames to increase resistance to external loads. These are ideal for use supporting existing piles where ground conditions require additional anchoring, as well as for realignment and repair where ground mount frames may become misaligned.

Installation: The Gripple Anchors can be quickly and easily driven into the ground using just hand tools. The innovative install and ‘flip’ of the PV Anchor accesses the soil’s engineering properties with minimal disturbance. The PV Anchor is then activated by tensioning the wire around the PV racking using a Gripple Dynamic tensioner – allowing the system to offer increased protection against uplift despite requiring considerably less materials.

What’s new in 2024? Along with new torque tube wire management products, HT has Wire Management guides that document best practices. The series, meant to act like an encyclopedia, will document best practices in wire management for multiple Tracker manufacturers and First Solar Series 6 modules.

Application: Wire Management

Material: Engineered polymer made of our industry leading HIRHSUV resin. High Impact modified, High Heat and UV Stabilized PA66.

Install: The bolt mount ratchet clamp has taken our award-winning Ratchet Clamp design and made it more versatile in installation method, cutting down on the size and space needed for installation by removing the metal mounting tab.

Key feature: Basically, you can use any mounting method you choose to mount the new Bolt Mount Ratchet Clamp.

Total MWs installed in U.S. by year-end 2022: 30+ GW

What’s new in 2024? As a global wire solutions provider (solar, eBOS) headquartered in Chapel Hill, NC, Voltage brings a streamlined and cost-efficient experience to our partners. Exceeding the average GW output annually has established us as leaders in an industry that rewards agility and responsiveness. Our service-focused, Voltage team is engaged at every stage via our eco-system of wiring solutions that encompasses engineering design services through to customized manufactured products, coordinated as-needed delivery times, and closing the loop with VR pre-construction views and training support.

A hybrid of our product and engineering expertise, the Reel PnP system is the result of customizing each row and reel to the exact specification of the installation. Ultimately increasing productivity and thereby eliminating costly labor time.

Next-generation technologies utilized in the manufacturing process enable the Lynx to provide greater efficiencies while reducing labor and material costs. The trunk bus system eliminates multiple traditional components on a utility scale solar installation. These improvements reduce the number of connections, potential variable challenges and the amount of equipment that requires upkeep and repairs throughout the lifespan of the solar installation.

State-of-the-art VR/3D rendering files enable engineers and pre-construction teams to accurately address revisions and design options, lessening the number of change orders and resulting in cost savings.

Fixed tilt and canopy

Number of pieces: Titan: 1,154 per MW; Titan Duo 1,130 per MW

Certifications: ASCE 7-10 & CPP Wind Tunnel Tested

Installation: A pile driver installs the pile foundations for TITAN racking. APA screw machines are attached to skid steers to drive the ground screws. With the TITAN Duo, 100 percent pre-drilling is offered to ensure any bedrock or hard obstructions do not cause significant delays during installation. The racking attaches to the foundations and can be adjusted in the field to maintain the proper array height and design.

Advantages: The TITAN’s unique asymmetrical design and innovative features allow for flexibility in the field while streamlining the install process. It has the lowest part count per MW and integrated wire management. The patented Gravity Clip reduces module install time by 35 percent. The 3-rail design is an excellent solution for bifacial modules, providing low backside shading. The TITAN has the industry’s strongest C-pile with opportunities for adjustment. The screws are telescoping providing 18” of adjustability for topography.

Number of pieces: varies for each project – avg. 548 pieces for a 12KW project

Installation: The Ready Rack Pre-Engineered Kit is great for smaller projects and comes in two module increments. The kit has multiple foundation types and provides a solution for all subsurface conditions. It comes with everything needed to install the racking and is delivered on a 4’x12’ pallet. Additionally, there is no need to source any pipes or concrete with this product. The layout and dimensions are site specific and can be easily referenced in the provided plans. The helical and ground screw foundations are simply installed by using a skid steer and auger attachment.

Advantages: Designed specifically for smaller residential and commercial solar installations, it comes with all required components and has approved engineering documentation already completed and included; just pick your parameters and go. The design is a simple configuration that allows contractors to install the system fast. A 10 kW system, for example, can be installed in one day. Integrated features allow for onsite adjustment and anchors paired with quick-install bracing make this simple system extremely robust.

Three pieces: Ground screw or helical, leveling flange, A-Frame.

Design: The helical piles or ground screws are driven with a rotary head. Then the A-Frame is attached to the piles with four bolts. The A-Frame uses a standard I-beam section to the solar tracker system. This allows seamless transition from driven I-beams to the A-Frames, leaving connection hardware the same. The leveling flanges allow for up to 20 in. of height adjustment to keep the A-Frame plum and level. The dual post design allows for ground screws or micro helicals for the foundation and are driven using a rock drill.

Advantages: The A-Frame advantage is its dual post design, allowing developers to substitute the traditional pile-driven foundation for a dual ground screw or dual helical foundation to accommodate rocky or softer subsurface conditions. The adjustability in the A-Frame also aids in dealing with topography and managing in-field adjustments to maintain the design of the array. Helicals are designed for softer soils, while ground screws are best suited for rocky or harder subsurfaces that have cobbles or other obstructions.

apasolar.com | Sales: sa***@ap******.com

Specialty: Residential and C&I <500 kW

What’s new in 2024? 2024 will include the introduction of SunTurf TT Ground Mount System and some new roof attachments while we gear up for a big release in the second half of the year with our new flat roof ballasted system.

Average row construction time: 4LX12 array 20K system installed within 1 day (10am-2pm)

Slope tolerance: Up to 27% slope east-west.

Certifications: UL 2703

Installation: No cutting, welding, or drilling. Adjust height and install posts with set screws. Pipe fittings attach quickly with set screws. Two-piece pipe caps make installation easy. Structural splice with set screws for bonding. Fast rail attachment with T-bolts. The SunTurf Ground Mount System easily integrates Helio Rails with Schedule 40 Steel Pipes. Combine SunTurf with SunModo Ground Screws or Augers and do a complete install of a 15-kW system with only one day on the job site. For a more interactive look at SunModo’s Ground Mount, check out this video.

Advantages: SunModo offers the next generation SunTurf Ground Mount System. The streamlined design combines the simplicity of a pipe-based system with next-level engineering. SurTurf Ground Mount is ideal for solar installers looking for a low cost high performance system that can accommodate a wide variety of soil conditions. No drilling is required to attach the aluminum rails to the horizontal pipe. The innovative swivel pipe cap kit can accommodate terrains up to 27% slope east-west and 120% slope north-south.

Specialty: C&I size projects. The universal design, manufactured from UV rated glass reinforced Nylon 6, enables the installation of all framed modules and stands up especially well in highly corrosive conditions near the ocean.

www.sollega.com | Sales: In**@so*****.com

What’s new in 2024? Mechatron Solar is now offering its new dual-axis M16KD AgriTracker featuring vertical diffuser columns to maximize light penetration to crops. Each M16KD AgriTracker supports 80 solar panels with 72-cut cells, or 72 panels with 144-cut cells, yielding over 35kW. The top-edge table height is 30 feet and the bottom edge is 15 feet, providing ample clearance for farm machinery. The ground coverage ratio ranges from 28% to 50% depending on panel type, thus the M16KD requires only 4 acres per MW of array. The gearless, hydraulic design drives through 360 degrees of Azimuth rotation and 60 degrees of Zenith inclination.

Mechatron Solar’s M16KD at World Ag Expo 24; Credit Chris Weber

The M16KD AgriTracker is manufactured in Stockton, California by Mechatron Solar, that manufactures unique, patented dual-axis photovoltaic trackers. With a ground coverage ratio of 28% to 50% (depending on panel type), the M16KD solution requires only 4 acres per MW of array. The gearless, hydraulic design drives more through 360 degrees of Azimuth rotation and 60 degrees of Zenith inclination.

Highly weather-resistant, the M16KD tracker withstands wind gusts of up to 115 mph; a version with heavier purlins is available for wind speeds up to 135 mph. The M16KD also withstands snow loads of nearly 35 psf, although snow loads have been demonstrated to shed readily in Canadian latitudes.

The flagship M18KD tracker supports 90 solar panels. The company’s unusually high-yield trackers have the highest energy density and the lowest ground footprint in the industry. Mechatron solar trackers include gearless azimuth trackers and gearless dual-axis trackers, which are designed to maximize performance with a lower operations and maintenance cost than other commercially available tracking systems. They have been successfully tested under different climate conditions rate structures constitute the best available solution for photovoltaic plant installations.

Mechatron was certified under UL 3703 in 2022 and completed a bankability analysis by Black & Veatch. The flagship tracker also features a new digital guidance system, along with a new optional design with eight columns to accommodate large format modules. The M10KD residential model features a reduced table size to support 49 panels, to accommodate limited space requirements.

The M18KD-20 carport tracker yields 40kW of power, is capable of 360 azimuth rotation and 0-25 degrees of elevation tilt.

Best suited for: Carports where available land space is limited or constrained.

Advantages of design: The M18KD-20 offers dual-land use. The single mast allows deployment with minimum parking area usage and provides uniform shade to vehicles while harvesting the highest possible energy from the space, yielding over 2,200 kWh/kW annually.

What’s new in 2024? Infinity Rack made waves in 2023 with a truly watertight solar canopy solution that is robust, simple to install, and looks fantastic from any angle. The system can use ANY solar modules with a frame and there are 21 “Standard” canopies to choose from. Or, we can instantly price out custom spans up to 41 feet deep that extend as wide as any property. All kits come with engineer stamped structural plan sets, including the site-specific footer design. Ready for 195MPH wind zones and extreme snow/seismic loads.

Avg. row construction time: Installs in almost the same timeframe as a typical, similarly sized (kWDC) ground-mounted array.

Best suited for: Any watertight shade solution for any environment.

Advantages: A Mechanically Watertight solar canopy with an Integrated PV Wire-Management Solution and an infinite range in design; including structural BIPV (Building Integrated Photovoltaics). 2605 Powder Coating is standard in black, white, or tan. Additional luxury finishing upgrades available.

How does it install? Once the engineered footers (concrete form or helical pilings) are set then the column bases attach using concrete anchors. There are detailed install manuals and videos but the process is very intuitive and mostly goes together with a half inch socket. Infinity Rack also provides our own in-house technician on your jobsite to train your team during their first Infinity Rack installation.

Certifications: NEC Compliant, UL in process

Paired Power

What’s new in 2024? Paired Power has seen tremendous interest in its PairTree product since it became available, growing its customer installations and inquiries. PairTree is a solar powered microgrid electric vehicle charger that can be popped up almost anywhere within a single day. It pairs solar energy with energy storage and the grid to charge up to two electric vehicles. PairTree has gained popularity because of its dependable and resilient power (available during emergencies when the grid may be out) and its low maintenance design (no trackers or moving parts). In January, PairTree became available for purchase in the U.S. via the GSA Advantage and Sourcewell lists, allowing military, state, and government contractors to purchase PairTree at the best listed price on the market.

Best suited for: Cities, corporations, military, government and commercial fleets.

Advantages: PairTree’s ability both to generate power from the sun and to store power from an existing grid connection (such as from a nearby parking lot light pole) makes it the ultimate resilient microgrid charger. PairTree was designed without moving parts to avoid risks of parts failure or ongoing maintenance. Its stable ballasted design also enables it to be wind rated for up to 130 mph wind zones.

Differentiators in construction: Each PairTree can be installed within a single day by a crew of two without heavy equipment (no cranes or forklifts required). Multiple units can easily be installed within one week by the same crew. Parking lot slope should be within 0.5% in either the E-W or N-S directions. The PairTree’s footprint occupies a standard 9×18 foot parking space but overhangs half of the adjacent spaces on either side so that additional PairTrees can be cascaded side by side to create a continuous solar canopy to meet the needs of larger lots or fleets. PairTree can be installed in roughly 8 hours without heavy excavation or equipment.

Electrical notes: PairTree provides one or two Level 2 EV charging ports per system using the industry standard J1772 EV interface. All wire management components are enclosed within either our battery system or structure and are thoroughly tested at the factory before deployment.

Solar Foundations USA

What’s new in 2024? We recently finalized construction of our new manufacturing facility in Round Lake, NY. The new facility enables us to increase our manufacturing capabilities and lower our production costs while providing the same high-quality products, installation, and customer support our clients enjoy and expect.

Row length range: Varies by design parameters (typically 140’ max)

Slope tolerances: Non-Rock Drill 15Degrees or 26.8%, with Rock Drill 10 degrees or 17.6%

Avg. row construction time: 6 hrs. (25 kw per 2-man crew)

Certifications: UL2703 Certified

How does it install? Ground screws (rock drilling when needed with screws pinned into the rock) or helical piles, welded beams, and galvanized hardware. We utilize a mini skid steer to install the screws or piles, then bolt and weld the system together.

Advantages: Extreme durability in high wind and/or snow load regions. System engineered to last a minimum of 75yrs with a 25yr residential and 50yr commercial warranty. Installation by company and company trained certified installers. Rock drilling capabilities of each crew in the field to ensure the system get installed regardless of subsurface rock or other substrates.

Best suited for: Residential Installations

Advantages: Specifically designed for residential installations utilizing our Patented ground screws or helical piers to expedite the installation process. Utilizing our legendarily robust ground structure components we can keep costs down and make these products financially within reach for your customers.

Differentiators construction or engineering services: Fast and easy installation of the foundations via ground screws or helical piers. Structural engineering is included and provided via our on staff PE and supplied via three sets of stamped drawings (or electronic if accepted by the AHJ) to allow you to submit with your permitting package. Our teams will install the structure and have it panel ready for you quickly, typically in a single day. This keeps your installers profitable on the roof while we set up and prepare the structure for you.

World4Solar

What’s new in 2024? The recently launched HelioWing Hurricane edition offers the strength to withstand wind speeds of up to 175 mph without snow. The steel (powder coated, American steel) structure and fastener strength has been increased from 50 ksi to 100 ksi to operate in coastal areas that experience tropical storms and hurricanes. The company plans on launching a large scale commercial high voltage battery and EV fast charging solution, Lumaport, in Q3 of 2024.

Best suited for: Residential and commercial applications.

Advantages: Reduced land use, modular, high curve appeal, scalable, easy-to-install, multi-functional hybrid solution for both off-grid and grid interconnection applications.

Differentiators construction or engineering services: Highly scalable installation process with generic structural and electrical calculation packets provided to assist with engineering and great customer service to support sales & integration questions.

Specialty: Headquartered in Ashland, Oregon, Stracker Solar has been manufacturing, selling and installing its state-of-the-art elevated dual-axis solar trackers since 2017. The pole-mounted Strackers are robust and elegant solar power systems specifically designed for maximizing distributed generation in urban environments.

![]() Row length range: Single pole-mounted design with 4 panels in a row in landscape orientation, 7 rows, (28 total)

Row length range: Single pole-mounted design with 4 panels in a row in landscape orientation, 7 rows, (28 total)

Slope tolerances: Mounts in any terrain condition. However, for allowing full tracking range, 45 degrees is the maximum recommended slope. Above that, tracking range needs to be customized to avoid array hitting the slope.

Certifications: UL 3703, Load-tested wind rating of 120 mph

Installation: The small 24-in. footprint of Strackers with a single pole enables easy installation across a wide variety of urban and rural environments, including hilly and difficult terrain. Foundation typically consists of 30-in. diameter reinforced piers. The 20-ft tall pole of the structure is tied to the foundation with four anchor bolts, making for easy relocation if ever needed.

The heart of the Stracker tracking system is a proprietary Drive-core (consisting of slew-drive actuators, electric motors, and control electronics), which is mounted at the top of the pole using a steel assembly and a structural bolting system. Then the array with the panels is lifted and secured atop the Drive-core.

Unique software capabilities: The control system incorporates a sophisticated, proprietary, GPS-based algorithm to track the precise location of the sun in the sky and adjusts the solar panel direction utilizing the Drive-core’s dual-axis movement capability. The enterprise-quality control system utilizes internal proximity sensors to assure the highest-quality algorithm solar tracking commercially available. It provides monitoring and automated procedures to protect against extreme weather events including high wind loads of up to 120 mph.

Advantages:

- Strackers provide maximum solar energy production with the smallest mounting footprint.

- They allow full use of the ground below with a 14-ft minimum clearance that easily accommodates semi-trailers, fire engines, buses and large farm equipment.

- Designed specifically for dual-use solar sites: parking lots, agricultural and industrial operations, campuses, other open spaces.

- Solar panels, electrical and mechanical equipment are lifted 14 to 35 ft above the ground, so there’s no need for fencing.

- Generates 50-70% more solar power than conventional fixed PV systems of the same size.

- Built in the U.S. of American-made steel.

Listen to more in-depth conversations on Solar Builder’s YouTube channel

Our most popular series include:

Power Forward! | A collaboration with BayWa r.e. to discuss higher level industry topics.

The Buzz | Where we give our 2 cents per kWh on the residential solar market.

The Pitch | Discussions with solar manufacturers about their new technology and ideas.

Tags: Aerocompact, Affordable Wire Management, agrivoltaics, Buyer’s Guide, CAB Solar, commercial and industrial, CPS America, FTC Solar, Full Tilt, Gripple, HellermannTyton, Nevados, OMCO solar, RP Construction Services, Shoals, Snake Tray, Solar FlexRack, Sollega, Soltec, Soltec Power Holdings, Stracker Solar, Sunfolding, SunModo, Terrasmart, Trina Solar, TrinaSolar, utility-scale