The method is easy to scale and automate and can be deployed to recycle large number of solar panels at the end of their life cycle.

Updated: Jun 05, 2024 08:49 AM EST

Representational image of solar panels

Researchers from Wuhan University and Northeastern University in China have developed a new approach for safe and environment-friendly recycling of solar panels. As an additional bonus, the approach is also more energy efficient and addresses concerns about an impending solar waste crisis in the future.

As countries look to move away from fossil fuels, there has been a surge in the adoption of solar cell technology to meet energy demands. With giga-watt-scale solar farms being established globally, there is also a concern about the imminent pile of waste that will emerge when the panels come to the end of their life cycle.

Although the technology exists to recycle components such as silicon, silver, and aluminum, the major components of solar power plants, it involves highly reactive nitric acid and generates some toxic waste that is difficult to dispose of.

Researchers at Wuhan and Northeastern universities in China have addressed these concerns by developing a more eco-friendly approach to recycling solar panel components.

A better way to recycle components

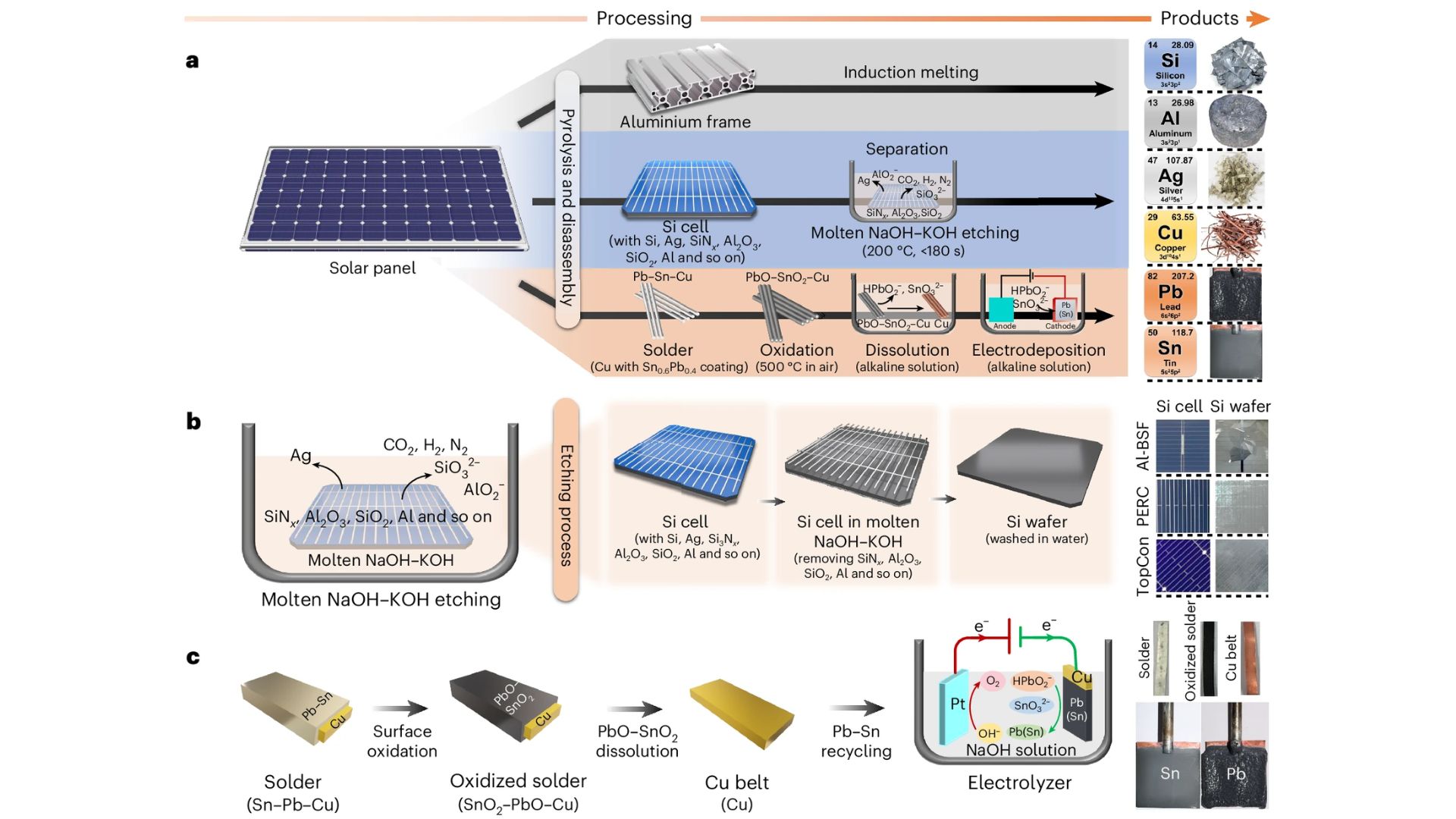

The current solar panel setup consists of an aluminum frame and backing, a glass cover with a non-reflective coating, and solder connecting the wires. Both the aluminum frame and glass cover can be easily removed and repurposed.

To separate the high-quality silicon in the solar cell from its silver wiring, recyclers use nitric acid and other chemicals to dissolve these high-value components. These are the tricky components in the recycling process.

The researchers in China replaced the acids with a molten mixture of sodium and potassium hydroxide (NaOH/ KOH), which is highly reactive with any component it comes in contact with.

After experimenting with various treatment methods, the researchers settled on a two-second dip followed by one for one to two minutes at temperatures of 392 Fahrenheit (200 degrees Celsius). The short exposures allowed layers of material to separate while remaining largely intact.

How do the panel components separate

The heat decomposes the polyvinyl layer, and the highly reactive hydrogen fluoride gas reacts with sodium hydroxide to form sodium fluoride. With silicon etching away, the silver wiring also comes out loose and floats in the water.

A filtration process can concentrate 99 percent of the silver even as the silver nitride layer can be recovered as a whole. The aluminum backing can also be removed in a water-based alkaline solution, leaving pure silicon wafer behind.

Elements such as tin, copper, and lead used in the solder oxidize in the air and can be recovered in a sodium hydroxide solution. Lead and tin can be separated using electroplating.

Adding water to the NaOH/ KOH mixture stops the etching reaction. The mixture can be concentrated and reused for another recycling round when required. The waste products from the entire process are sodium silicate and sodium aluminate, which are non-toxic and have wide industrial uses.

A life cycle assessment conducted by the researchers showed that recycling one kilogram of solar panels with their approach reduced carbon emissions by 14 kg and power usage by a factor of 220.

By scaling up and automating this approach, the researchers are confident that we can handle any volume of solar panels when they reach the end of their life cycle.

RECOMMENDED ARTICLES

The Blueprint Daily

Stay up-to-date on engineering, tech, space, and science news with The Blueprint.

ABOUT THE EDITOR

Ameya Paleja Ameya is a science writer based in Hyderabad, India. A Molecular Biologist at heart, he traded the micropipette to write about science during the pandemic and does not want to go back. He likes to write about genetics, microbes, technology, and public policy.

POPULAR ARTICLES

RELATED ARTICLES

This post was originally published on 3rd party site mentioned in the title of this site